powertrain

Complete traceability of the whole process and maximum flexibility in the production.

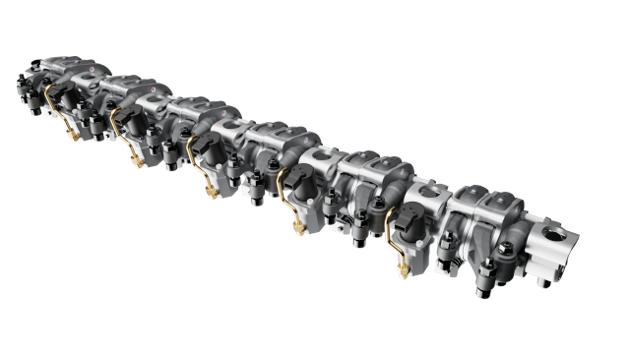

Powertrain: our solutions

Streparava internally designs, tests and produces powertrain components for various application. A business unit started since 1995 with the production of rocker arms assemblies for heavy duty engines. Streparava has since widened the applications and products portfolio to include crankshafts, camshafts, engine braking systems, connecting rods, fuel injection components and transmission assemblies.

All started in 1995.

In Streparava we manage the whole lifecycle of the product: from the design made according to customer specifications, to the prototype production and testing, product validation and industrialization. Everything done with complete traceability and extreme flexibility in the production: from small numbers prototypes to the production of thousands of units per day.

In Streparava we can rely on the most advanced technological solutions and a great amount of experience in the choice and use of materials. We are specialized in precision machining of components produced from forging, casting or aluminium as well as assembly of complex systems, with the use of fully automated lines for large volumes.

Production

technology and process development

Streparava follows a policy of constant update regarding strategic competences, tools, equipments and market processes, applying the most modern methods of industrial automation and digital transformation.

Plant

Presence in the world

With 9 facilities in the world, Streparava produces chassis and powertrain components with an high degree of precision, supplied to the major OEMs for motorcycles, automobiles, buses, industrial and commercial vehicles.